Thread types: what are they and what are their characteristics?

8 Feb , 2023

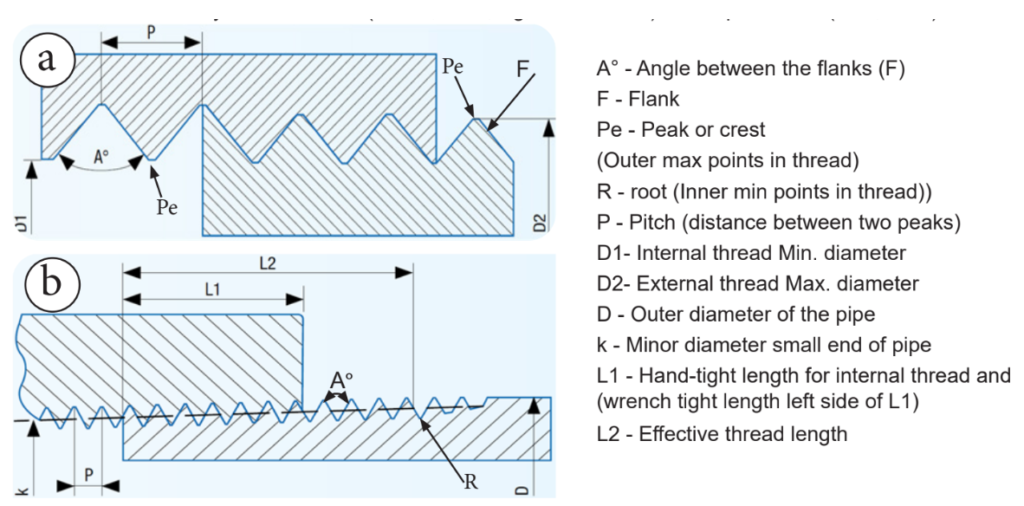

A thread, also known as a screw thread, is a helical-shaped thread passing through an axis with equal space (pitch) by means of different shapes (triangular thread, square thread, trapezoidal thread, and others).

The thread helps convert rotary motion into linear motion. Threads are used to temporarily connect two components, such as cable glands, fittings, and other electrical components.

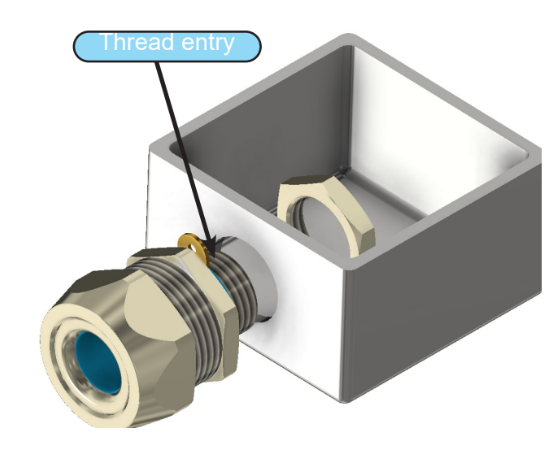

What is a thread entry?

The entry thread allows one system to be connected to another. For example, cable glands are connected by male threads through a through-hole tightened with a lock nut (see fig. 2).

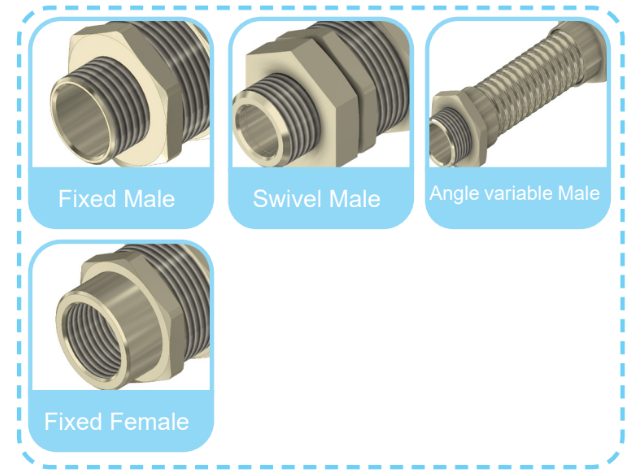

There are two types of entry threads: male threads and female threads (see fig. 3). At Euro2000, we have different types of male threads: fixed male thread, swivel male thread, and variable angle body with male thread (see fig. 3).

What are the various types of threads and how are they identified?

Threads can be classified based on two main types, which in turn can then be subdivided according to specific characteristics: a parallel or cylindrical thread (metric, GAS, Pg, UN, and UNEF) and tapered thread (NPT, GAS). The following image shows the details of these two types of thread.

Parallel or cylindrical thread

Parallel or cylindrical thread can be classified according to several characteristics. Let’s review them in detail.

Metric thread

The ISO metric thread is the most common thread and the globally standardized thread. It usually ensures IP sealing with the use of a gasket. The unit of measurement is in millimeters (mm).

Reference standards:

- ISO 68-1: 1998-12 “ISO general purpose screw threads —. Basic profile — Part 1: Metric screw threads”

- ISO 262: 1998-12 “ISO general purpose metric screw threads — Selected sizes for screws, bolts and nuts”

- ISO 965-1: 2017-11 “ISO general purpose metric screw threads – Tolerances – Part 1: Principles and basic data”

- ANSI B1.13M-2001 “Metric Screw Threads – M Profile”

Parallel GAS cylindrical threads

ISO 228 parallel gas cylindrical threads are usually called pipe threads with a non-pressure-tight joint. They usually ensure IP sealing with the use of a gasket. The unit of measurement is in inches.

Reference standards: ISO 228-1: 2000-09 “Pipe threads where pressure-tight joints are not made on the threads — Part 1: Dimensions, tolerances and designation.”

PG threads

The Panzer-Gewinde (Pg) thread was introduced in Germany and is used to connect electrical pipes and fittings or cable glands. The Pg thread has a small pitch between the peaks, unlike other types of threads. The unit of measurement is in millimeters (mm).

Reference standards: DIN 40430: 1971-01 “Steel Conduit Thread; Dimensions”

UN, UNS, and UNEF threads

Unified UN, UNS, and UNEF threads, as defined in ANSI/ASME B1.1, are threads in accordance with ISO standards in terms of their diameter-pitch combinations, designations, and tolerances for inch threads of 60° triangular shape.

There may be additional letters in the designation. They usually ensure IP sealing with the use of a gasket.

Reference standards: NSI/ASME B1.1 “Unified Inch Screw Threads.”

Tapered thread

Like parallel or cylindrical threads, a tapered thread is also classified according to different characteristics.

NPT tapered thread (National tapered thread for pipes)

A NPT thread is usually known as a pressure-sealing thread and was introduced in the United States. It usually provides IP sealing without a gasket due to the pressure seal between the flanks. The unit of measurement is in inches.

Reference standards: ANSI/ASME B1.20.1 – 1983 “Pipe Threads, General Purpose”.

GAS tapered threads

The gas tapered thread is usually known as a pipe thread with a pressure-tight joint. It usually provides IP sealing without the use of a gasket due to the pressure seal between the flanks. The unit of measurement is in inches.

Reference standards:

- ISO 7-1: 1994-05 “Pipe threads where pressure-tight joints are made on the threads -. Part 1: Dimensions, tolerances and designation.” BSPT – the tapered male thread (R) and tapered female thread (Rc).

- EN 10226-1: 2004-07 “Pipe threads where pressure tight joints are made on the threads Part 1: Taper external threads and parallel internal threads. – Dimensions, tolerances and designation.”

- EN 10226-2: 2005-08 “Pipe threads where pressure tight joints are made on the threads Parrt 2: Taper external threads and taper internal threads – Dimensions, tolerances and designation.”

How to select the thread according to the application?

Threads are used in a wide variety of applications:

- Infrastructure

- construction machinery

- food, chemical, and pharmaceutical industries

- energy industry

- service sector

- railway sector

- Naval sector

- industrial sector

Depending on the application, sector, and type of project, it is useful to know how to choose the most suitable thread. Here are a few hints.

In the case of a completely new project:

- Assess the IP sealing status

- Assess the operating temperature range. If the operating temperature is very high, a pressure-tight thread (NPT or ISO 7/1 GAS thread) should be selected to maintain the IP protection.

- Assess the location of the project. For example, based on step 2 described just now, a US-based company would choose an NPT thread, while a European one would choose an ISO7/1 GAS one.

In the case of an existing project:

- Assess the IP sealing status

- Assess the operating temperature range

- Assess the type and size of the counterpart system thread.

You can download here an in-depth document on threads and a list of those manufactured by Euro 2000. If you need more information, do not hesitate to ask!