Safeguarding Hazardous Environments: How Euro2000’s Anti-Static Conduit Systems Prevent Sparks and Static Risks

1 Sep , 2025

Gasoline vapors are highly flammable when their concentration in air is between 1.4% and 7.6%; even a single spark can trigger a fire or explosion. Outside this range, ignition is unlikely, but the risk remains significant in hazardous environments and at Euro2000, safety is our top priority. This article explores the science behind static electricity, the distinctions among anti-static materials, and how Euro2000’s Conduits for electrical cables are purpose-built to prevent static-related hazards in the world’s most demanding industries.

Static Electricity: What It Is and How It Forms?

Static electricity is a form of electricity that results from an imbalance between positive and negative charges within or on the surface of a material. When two materials rub against each other, electrons (negatively charged) move from one object to another, leaving that one object with an extra negative charge and the other with extra positive charge. This process is known as the triboelectric effect.

Examples and Hazards in the Industrial Sector

When you walk across a carpet and then touch a metal doorknob, you might feel a small shock. That’s because your body picked up extra electrons from the carpet. When you touch the metal, the built-up charge suddenly moves from you to the doorknob, causing a tiny zap. In industrial environments, static electricity can be far more dangerous, as accumulated charges may discharge suddenly (electrostatic discharge, or ESD), potentially igniting flammable gases or damaging sensitive electronics.

Figure 1: Static Electricity Illustration

Conductive, Static Dissipative, Anti-Static and Insulating Materials

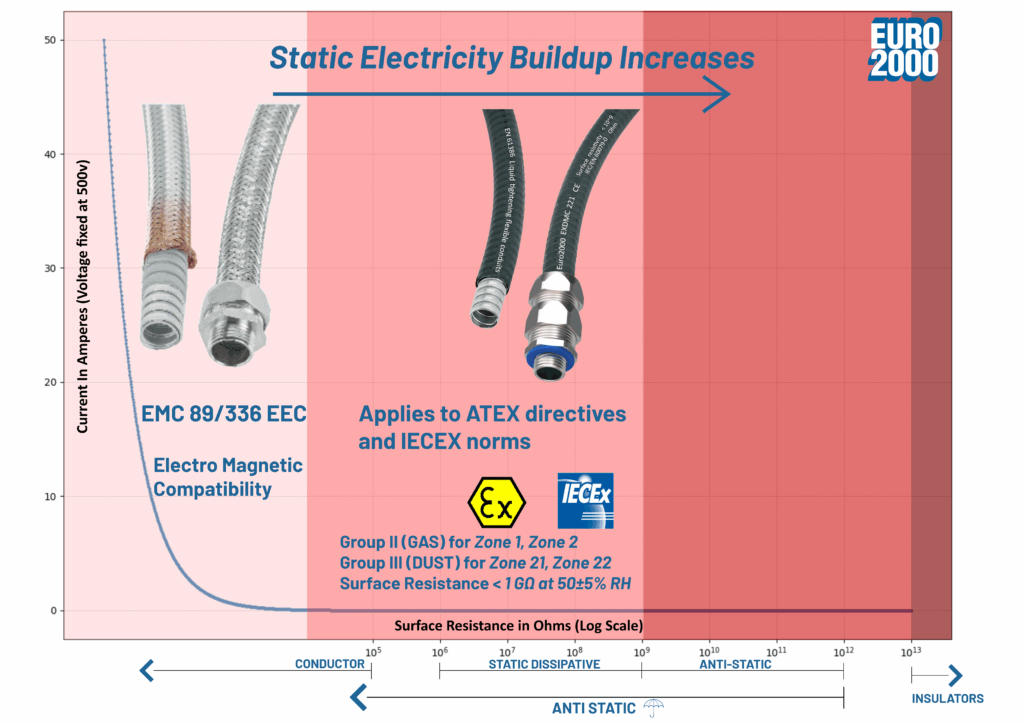

Different types of materials display different behaviors based on a factor called “Surface Resistivity’ which helps in identifying the resistance to electric current for those materials.

Surface resistivity is the resistance to electrical current flowing along the surface of a material, measured in ohms (). It is the most important property as it determines how easily static charges can move across the surface and be dissipated.

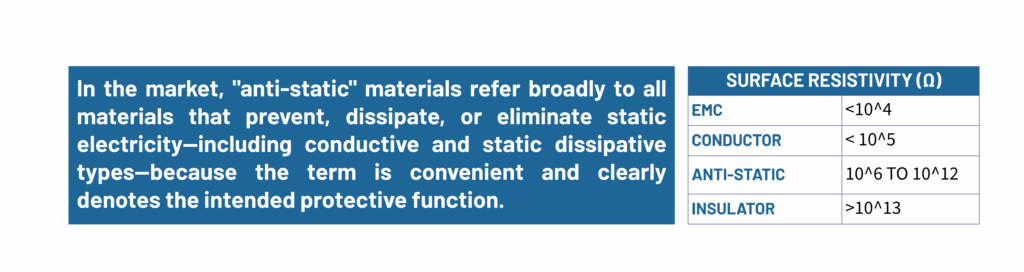

In real-world applications and the marketplace, the distinctions between these categories are often blurred. The term “anti-static” is widely used as a catch-all label for any material that helps control static electricity—regardless of whether it is technically conductive, static dissipative, or anti-static by strict definition. This is because “anti-static” directly communicates the material’s function: preventing static electricity discharge.

The following table shows the differences between materials based on their surface resistivity in more detail.

| Material Type | Surface Resistivity (Ω) | Example of EURO2000 Products | Function | |

Umbrella Term: ANTI-STATIC | Conductive | <10³Ω | Copper braids, DMT-EMP, | Instantly eliminates static charges by providing a direct path to ground |

| <10⁵Ω | Steel Braids, DMT, PA6V2-TR Conduit | |||

| Static Dissipative | 10⁵ – 10⁹ | EX-DMC/EX-DMCX/EX-DMCXX(<10⁹ Ω) | Safely dissipates static over time, preventing sudden electrostatic discharge (ESD) | |

| Anti-Static | 10⁹ – 10¹² | NYLOHM junction box | Minimizes static buildup by reducing triboelectric charging on surfaces | |

| Insulative | > 10¹³ | Standard PVC-coated conduits without anti-static additives | Blocks charge movement entirely, acting as an electrical barrier |

Anti-Static Design in Conduit Systems

Anti-static design aims to prevent the accumulation of static charges in conduit systems, reducing the risk of sparks and ignitions in hazardous environments such as petrochemical plants, mining, pharmaceuticals, etc.,

Techniques

- Material Selection: Use of anti-static polymers to lower surface resistivity.

- Surface Treatments: Application of conductive coatings or treatments to enhance charge dissipation.

- Grounding Systems: Ensuring all conductive parts are properly grounded to allow safe discharge of static electricity.

EURO2000 Anti-Static Conduit Systems

Figure 2: Surface Resistance v Current at 500 volts

EX-DMC is a specialized conduit made from hot-dip galvanized steel(also available in stainless steel 304 and 316L variants – called as EX-DMCX and EX-DMCXX, respectively) and coated with a smooth, anti-static PVC layer. Its standout feature is this anti-static coating, designed to meet IECEx and ATEX standards (IEC/EN 60079-0), specifically in Section 7.4.2.A for Group II (Gas) in Zone 1 and Zone 2; and section 7.4.3.A for Group III (dust) in Zone 21 and Zone 22 which require surface resistivity less than 10⁹ ohms for safety in explosive environments, tested according to Section 26.13 (which explains about surface resistance testing procedures). For Ex-Products (referring to ATEX and IECEx directives), it is mandatory to have the anti-static property.

With a surface resistivity of less than 10⁹ ohms, EX-DMC safely dissipates static electricity, helping prevent sparks and ignition risks. It can be used with RPM-N and RPF-N cable gland fittings.

| Product Series | Core Material, Coating and Features | Anti-Static Properties | Application Relevance (below mentioned products are suitable for Ex application) | Suitable fitting / fitting cable gland |

| EX-DMC/EX-DMCX/EX-DMCXX | Hot Dip Galvanized Steel/Stainless Steel AISI 304/Stainless Steel AISI 316L + Smooth anti-static PVC coating | Surface resistivity <10⁹ ohms, meets IECEx/ATEX standards | Specifically designed for explosive environments, ESD protection, high mechanical strength. | IECEx / ATEX application: RPM-N, RPF-N Standard application: AM RP MF / AM RP FF / AM RP MG / AM RP CURVO / AM MF |

| DMT-EMP | Flexible hot deep galvanized steel with thin PVC layer + EMC protection with copper wire surface | Surface resistance <10³ ohms for EMI shielding | Electromagnetic interference protection, ESD protection and EMC. | |

| DMT/DMTX | Galvanized/AISI 304 steel with thin PVC layer + Galvanized steel Wire over braided | Metal braiding provides conductive path <10⁵ ohms | Heavy-duty industrial applications, ESD protection and EMC. | |

| EMC Screening Braid | AISI 304/AISI 316L/Copper, Braided Wire | Designed for explosive environments per IEC 60079-0,7, with surface resistance <10³ / <10⁵ ohms | Hazardous industrial applications, ESD protection, EMC, IECEX and ATEX | IECEx / ATEX application: PM-SA, PF-SA Standard application: Fitting braided cable gland |

DMT-EMP is a specialized conduit certified to EMC 89/336 EEC standards for protection against electromagnetic interference. With a surface resistance below 10³ ohms, it effectively shields against EMI.

Euro2000’s anti-static conduit systems bridge the gap between safety and innovation, transforming hazardous environments from potential ignition zones into protected spaces. By harnessing anti-static materials, surface resistivity control, and rigorous adherence to IECEx and ATEX standards, these solutions ensure that static electricity is swiftly neutralized before it can spark disaster. From the science of static to the engineering behind each conduit, Euro2000’s commitment to safeguarding people and assets is woven through every detail—making safety not just a feature, but a promise fulfilled from the ground up.

To learn more about the full potential of our products, please consult our Complete guide to flexible conduit system.