IK Protection Rating: Classification and Impact-Resistant Conduits

21 Jan , 2026

Modern industrial and commercial electrical installations are constantly exposed to mechanical stresses, whether it is an accidental drop of tools on components or intentional damage in public areas. To ensure the safety of people and the reliability of electrical equipment, the precise selection of IK ratings (which is recognized as the international standard IEC 62262) for impact resistance is vital. This article explains the principles behind IK ratings, their significance, and how choosing Euro 2000 conduits ensures dependable impact protection for your installations with some of our applications.

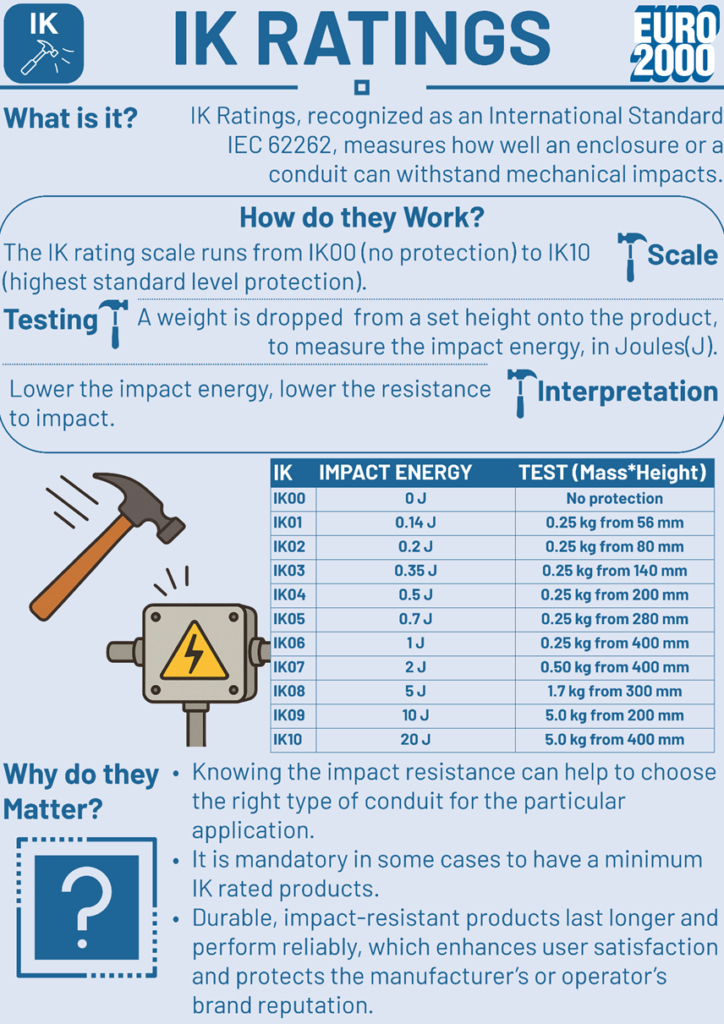

Understanding IK Ratings protection

The IEC 62262 (EN 62262) standard assigns an IK code from IK00 (no protection) to IK11 (50 J) that quantifies the energy an enclosure can withstand without functional failure. Each step represents a defined strike, e.g., IK08 equals a 1.7 kg steel hammer dropped 300 mm (5 J).

| IK Code | Impact Energy (J) | Typical Test Mass & Drop Height |

| IK06 | 1 J | 0.25 kg × 400 mm |

| IK08 | 5 J | 1.7 kg × 300 mm |

| IK10 | 20 J | 5 kg × 400 mm |

| IK11 | 50 J | 10 kg × 500 mm (added 2021) |

To obtain an IP certification, performing IK testing is a mandatory step. While IP ratings focus on protection against dust and water ingress, the IK rating specifically measures resistance to mechanical impacts. In fact, IK testing is typically carried out before assigning the final IP rating, ensuring that both ingress protection and impact protection are properly validated.

IK Performance Levels

IK08 Heavy-Duty Rating (5-7 J)

Equivalent to a 1.7 kg hammer dropped 300-400mm, this rating handles routine industrial impacts including dropped tools, maintenance contact, and equipment vibration.

IK10 Maximum Standard Rating (20 J)

Withstands a 5 kg hammer dropped 400mm, suitable for exposed installations, public areas, and locations subject to deliberate abuse or severe mechanical stress.

The coordinated IK ratings across conduits, fittings, and glands ensure complete pathway integrity even after significant impact events, maintaining both electrical continuity and environmental sealing.

Impact-Resilient Euro 2000 Protection Systems

STANDARD SYSTEMS

Standard systems provide essential mechanical protection for day-to-day industrial electrical installations. These assemblies feature impact resistance at the heavy-duty IK08 level (6 J), sufficient to withstand accidental tool drops, maintenance impacts, and routine industrial knocks. The TZR rigid steel tube elevates protection to the maximum IK10 level (20 J) for exposed runs requiring exceptional durability.

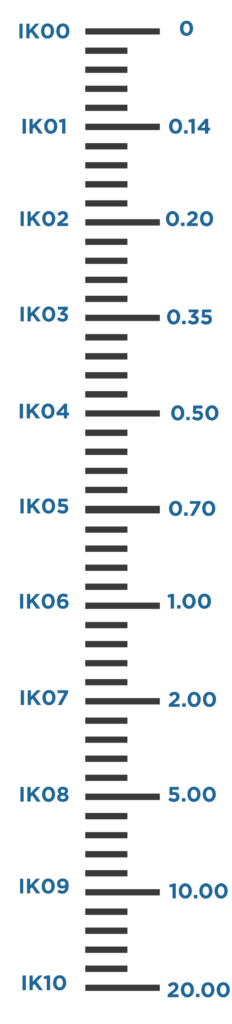

Standard Conduit Systems (DMC + Fittings)

This flexible metal conduit system combines galvanized steel DMC conduit with precision nickel-plated brass fittings and cable glands – AM-MF and AM RP-MF, forming a complete solution certified to EN IEC 61386. It offers high durability with an IK08 impact rating (about 7J), IP66/67/68 protection, 1000 N tensile strength, and 1250 N compressive strength, all while maintaining electrical continuity throughout.

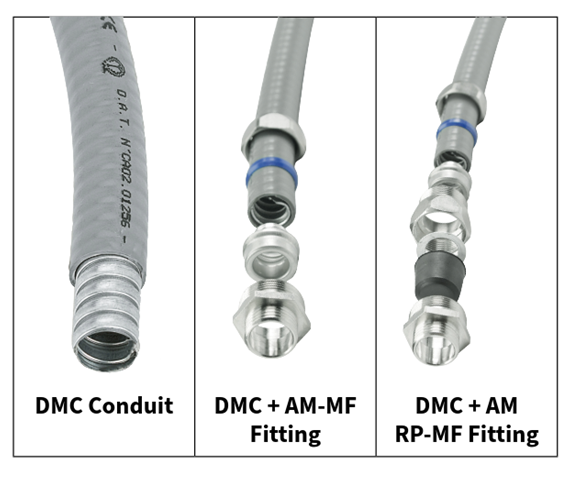

Rigid Conduit Systems (TZR Tube + Fittings)

The TZR rigid steel tube, made from Fe360 steel with hot-dip galvanization per EN 10240, offers a top impact rating of IK10 (20 J), withstanding a 5 kg hammer drop from 400 mm, and provides 4000 N compressive strength, 1000 N tensile strength, and excellent flame retardancy across a broad temperature range (–25°C to +400°C). When combined with the INR series quick-coupling fittings and cable glands, crafted from nickel-plated brass with IK08 impact resistance (6 J), the system ensures robust protection including IP66/67/68 ratings, tensile strengths around 1000 N, compressive strengths up to 1250 N, and maintains electrical continuity. These fittings feature quick-assembly designs that accelerate installation and operate reliably from –40°C to 105°C, delivering a durable, high-performance cable solution.

ATEX/IECEx SYSTEMS

These explosion-proof systems are certified for use in hazardous zones where flammable gases or combustible dust may be present. All components maintain impact resistance at the IK08 level (6-7 J) while featuring anti-static materials and enhanced sealing for explosive atmospheres for zone 1, zone 2, zone21 and zone 22.

Ex Conduit System (Ex-DMC/Ex-DMCX/Ex-DMCXX + Cable Glands)

The Ex-DMC anti-static conduit offers IK08 impact resistance (6 J) and is designed to prevent electrostatic charge buildup with surface resistivity under 10⁹ Ω, meeting IEC/EN 60079-0 Section 26.13 requirements for explosive environments. It operates between –40°C and +105°C, provides IP67 protection, and delivers 1000 N tensile and 1250 N compressive strength. Paired with the RPM-N/RPF-N explosion-proof cable glands, rated IK08 (7 J at –40°C) and certified for ATEX Device II (2G, 3G, 2D) with “Ex eb,” “Ex nR,” and “Ex tb” protections. This combination ensures high impact resistance, reliable sealing (IP66/67/68), and safe operation from –35°C to +85°C in hazardous areas.

Ex Tube System (TZR + Quick Coupling Fittings)

This explosion-proof rigid system combines TZR tubes, retaining IK10 impact resistance (20 J) at –25°C and flame-proof rigidity for Zone 1, with certified Ex quick-coupling fittings and cable glands. For corrosion environment choose the stainless steel AISI 304 tube TXR or the stainless steel AISI 316L tube TXR316L.

These INR series fittings and cable glands (INR-TF, INR-TM, INR-TT, INR-TPM) provide IK08 impact resistance (7 J at –40°C), ATEX Group II (2G, 2D) certification with “Ex eb”/”Ex tb” protection, IP66/67/68 sealing, and operate from –35°C to +85°C. They ensure reliable electrical continuity, corrosion resistance, and fast installation, delivering robust mechanical and environmental protection in hazardous areas.

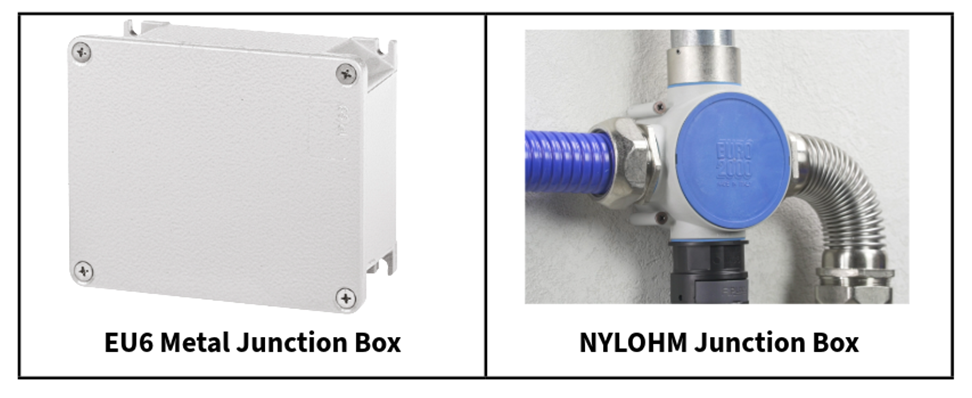

JUNCTION BOXES

The EU6 junction box achieves IK08 impact resistance (5 J @ 20°C) through die-cast aluminium construction. Operating from –20°C to +80°C with IP66/67/68 protection, it provides secure cable termination. Captive earth screws and anti-corrosion coating ensure reliable electrical performance across seven standard sizes. The NYLOHM junction box achieves IK07 impact resistance (2 J) through Polyamide (PA66) construction. Operating from –50°C to +120°C, it has anti-vibration properties and non-openable accidentally and ensures an IP68 protection.

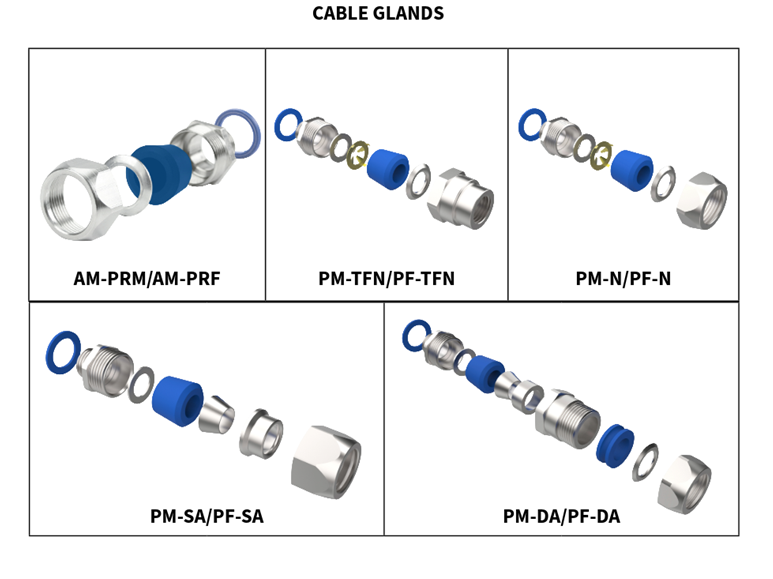

CABLE GLANDS

- AM-PRM/AM-PRF: Nickel-plated brass cable glands with thermosetting elastomer seals, offering IK08 (6 J) impact resistance, IP66/67/68 protection, Class B retention, electrical continuity, and corrosion resistance.

- PM-TFN/PF-TFN: Threaded-head glands for panel mounting, rated IK08 (7 J at –40°C), with ATEX approval, deep thread engagement, and optional EMC shielding.

- PM-N/PF-N: Basic cable glands for explosion-proof use, providing IK08 (7 J at –40°C) impact resistance, with or without EMC, and a quick-tightening design for fast hazardous area installation.

- PM-SA/PF-SA: Armoured glands for shielded cables; IK08 (7 J at –40°C), cone-locking ensures 360° armour contact for EMC, supporting both metallic braiding and wire armour.

- PM-DA/PF-DA: Double-seal glands with IK08 (7 J at –40°C) impact rating, dual elastomer seals for maximum protection, accommodating larger armoured cables with enhanced retention.

—> See our cable glands catalogue.

Selecting the Right IK Level for Your Requirement

For the most demanding scenarios involving critical outdoor assets such as substations or tunnels which are subject to severe vandalism or flying debris, Euro 2000 offers custom conduit assemblies engineered to meet IK10 and IK11 ratings, providing maximal mechanical protection.

IK ratings translate the abstract idea of “ruggedness” into quantifiable joules, giving designers a common language to balance risk, cost, and durability. Euro 2000’s conduits, which are backed by reinforced cores, rigorous IEC testing, and decades of field use offer dependable options from IK08 through IK10 and beyond, ensuring installations remain secure long after the first impact lands.

Contact us for a consultation and further guidance on IK classification.